Designed to Perfect Every Particle

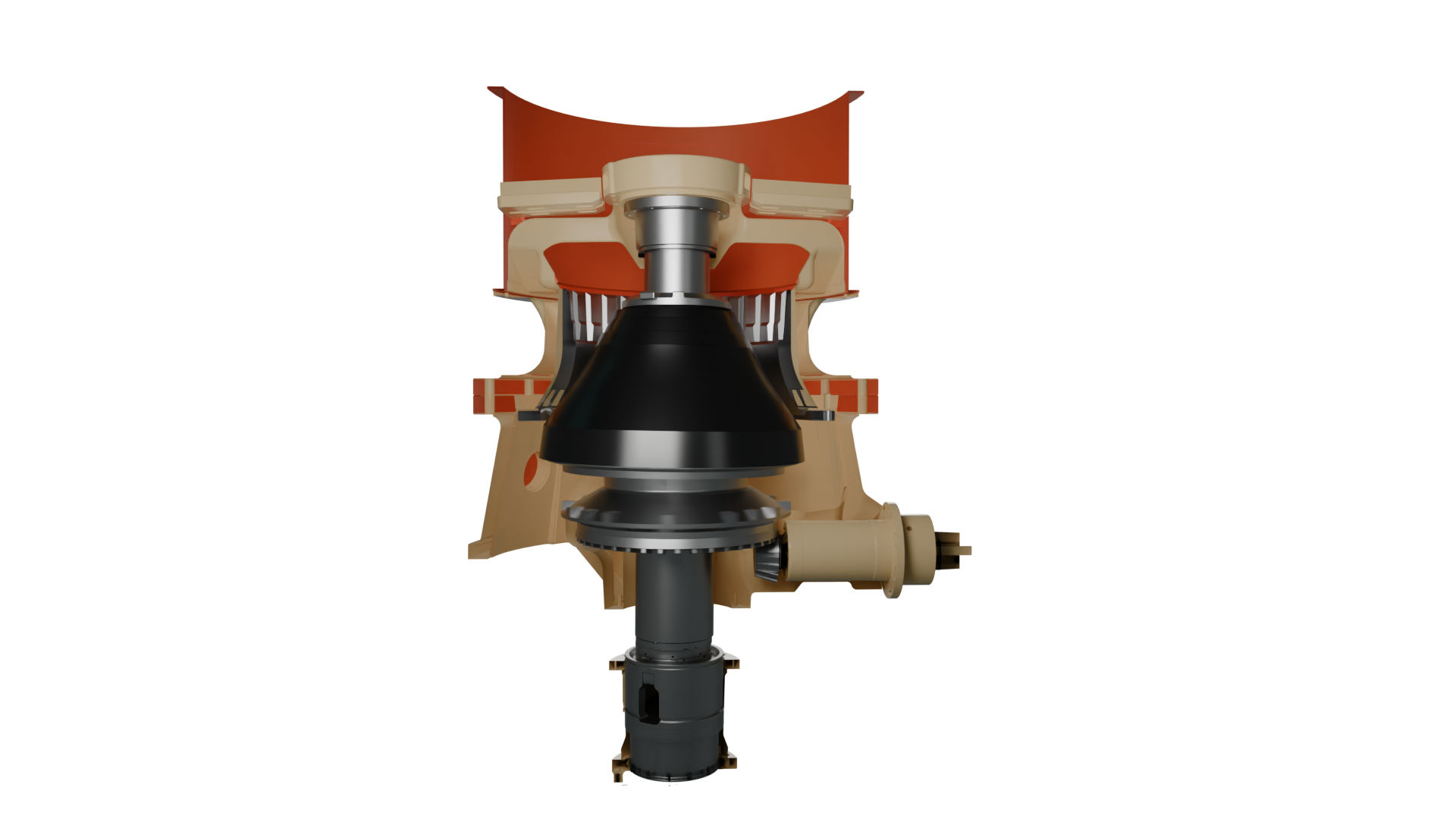

From secondary to fine crushing, the Mechtech Cone Crusher delivers reduction through steady compression. A reinforced structure, balanced motion, and hydraulic systems keep material flow predictable and output precise.

Play