Dedicated Customer Teams & Agile Services

Our worldwide presence ensures the timeliness, cost efficiency compliance adherence required to ensure your production timelines are met.

Overview

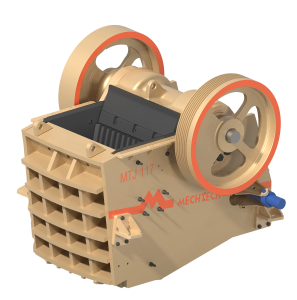

Mechtech’s top-of-the-line MTJ-type jaw crushers are designed specifically for primary applications where resizing is the primary goal. They allow the material to be handled within the confines of your crushing plant. The jaw crusher must have a good and homogeneous feed level to perform optimally.

Salient Features

HYDRAULIC JACKS

Hydraulic jacks help in the CSS range which has a significant effect on product gradation, capacity, and power draw.

LARGE FEED ACCEPTANCE CAPABILITIES

The large feed enables crush both tough feed materials like rocks in quarry fields and hard materiallumps in the mineral industry effectively and economically.

HEAVY-DUTY WELDED FRAME DESIGN

The plate takes heavy impacts from the material and protects the swing jaw, shaft, and bearing during crushing. It also helps to direct material into the crushing chamber.

HIGH CAPACITY WITH A HIGH REDUCTION RATIO:

The jaw crusher's bulk density, crushability, and size distribution result in a high capacity and reduction ratio

OPTIMIZED NIP ANGLES

Jaw crushers have nip angles between 16–23°.A good nip angle means a high throughput capacity of the crusher.

| DESCRIPTION | UNIT | MTJ-153 | MTJ-131 | MTJ-129 | MTJ-128 | MTJ-118 | MTJ-117 | MTJ-906 | MTJ-122 | MTJ-902 | MTJ-753 | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| APPLICATION | PRIMARY | SECONDARY | |||||||||||||

| FEED OPENING | mm inch |

1500x1300 59x51 |

1300x1130 51x45 |

1200 x 900 48x 36 |

1200x830 47x33 |

1041x838 41x33 |

1092x685 43x27 |

914x609 36x24 |

1219x254 48x10 |

914x254 36x10 |

762x381 30x15 |

||||

| FEED SIZE | mm inch |

1170 46 |

1070 42 |

800 48x 36 |

750 30 |

750 30 |

650 25 |

550 22 |

200 8 |

200 8 |

300 12 |

||||

| CAPACITY | Tph | 480 - 1160 | 330-960 | 200 - 800 | 165-790 | 150-565 | 150-400 | 80-300 | 45-150 | 25-90 | 30-90 | ||||

| CSS RANGE | mm inch |

150 - 300 5.1-5.9 |

125-300 4.9-11.8 |

100-275 4.0-11.0 |

75-275 2.9-10.8 |

75-225 2.9-8.8 |

75-185 2.9-7.2 |

75-150 2.9-5.9 |

30-75 1.1-2.9 |

25-60 1-2.3 |

35-75 1.3-2.9 |

||||

| LUBRICATION | GREASE | ||||||||||||||

| POWER | kW Hp |

1200 270 |

160 215 |

160 215 |

132 180 |

110 150 |

90 120 |

75 100 |

55 75 |

37 50 |

30 40 |

||||

| MECHANISM | SINGLE TOGGLE OVER HEAD ECCENTRIC | ||||||||||||||

FAQ

The MTJ jaw crusher is built to handle various feed material, but it has the following

limitations:

The top size should not exceed the 80% dimension of the width of the crusher .However,

occasionally the bigger feed size can be handle is the 3rd dimension is bigger and fed

diagonally into the crushing chamber.

Prior to entering the crushing chamber, fine material with a particle size equivalent to the

closed-side setting should be removed. Therefore, it will increase the crushing efficiency and

reduce the wear and tear on the jaw plates.

Our jaw crusher’s line includes: MTJ and DTJ series.

MTJ Series Jaw Crushers are grease lubricated crusher and DTJC Series Jaw Crushers are oil

lubricated crushers.

If the material is easily crushed and not excessively abrasive, single toggle jaw crushers can

be the best choice.

If the material is hard and abrasive in nature, double toggle jaw crusher (DTJC Series) can be

the best choice.

Determine the Jaw Crusher size for your application using the following information:

• A maximum material lump or largest size expected to be crushed

• Tons per hour rate needing to be crushed

• Desired size of discharge material needed

• Operating hours per day

Crushers can be customised based on your expectations. Working with a skilled material handling solutions partner like Mechtech is the best approach to locate the perfect crushers

for your specific operation. We assist you in finding the apt solutions to extract material,

break it down into usable output, and deliver it to market as economically and efficiently as

possible. The appropriate partner can assist you in developing a unique crushing circuit to

increase efficiency and improve your business.

Case Studies

JAW

Jaw Crusher-Working of the top-of-the-line series

Mechtech’s top-of-the-line MTJ-type jaw crushers are designed specifically for primary applications where resizing is the primary goal…

About Jaw Crusher

Facts You Need To Know About Jaw Crusher

Initially, there is a need to crush the materials obtained by quarrying/explosion in the Mining and Construction sectors to decrease them to a small size to be used…