Precision crushing. Proven performance.

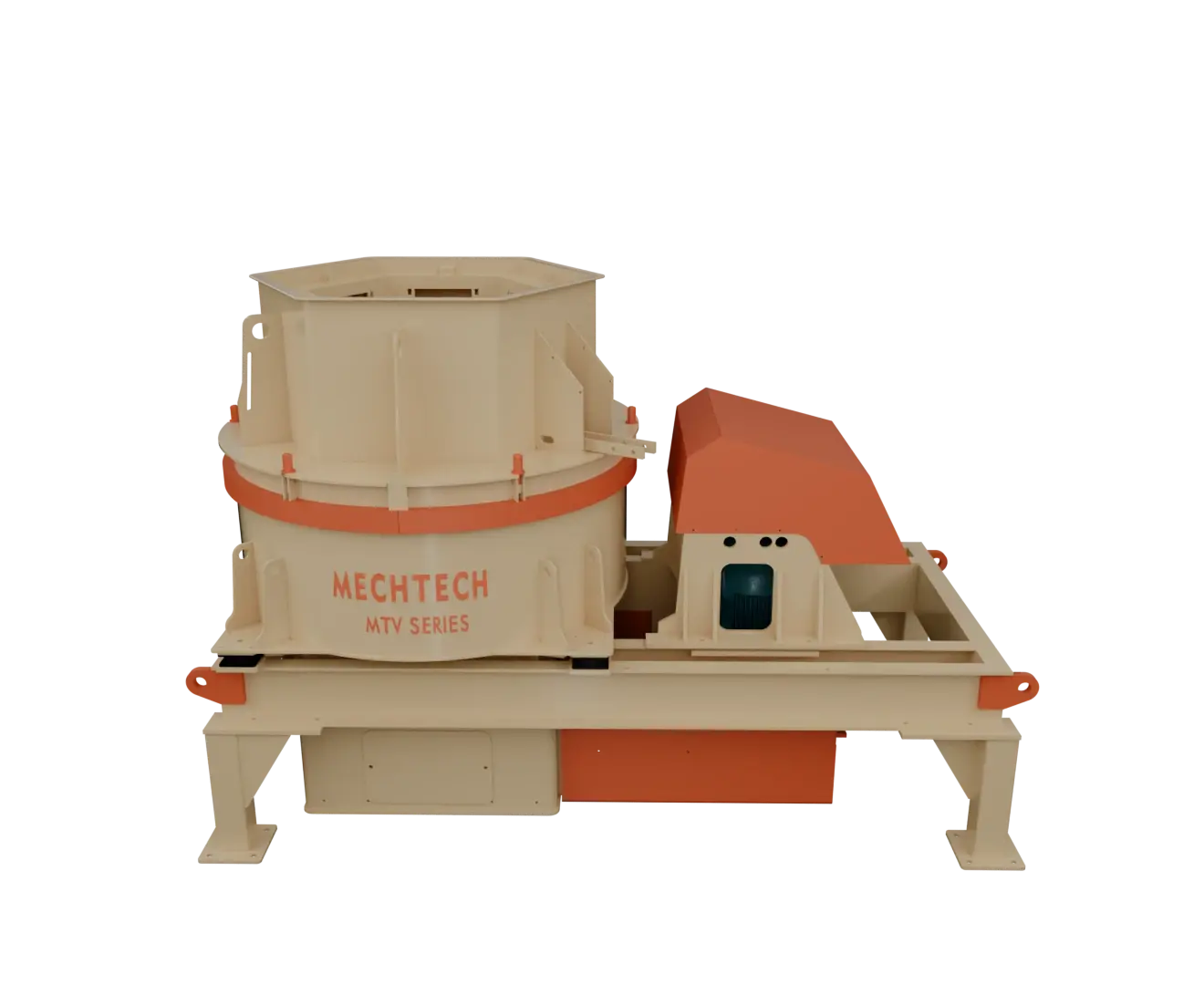

Mechtech Vertical Shaft Impactors are engineered for high-performance crushing, delivering superior shaping, consistent output, and reliable efficiency for demanding applications.

Play

Vertical Shaft Impactors are engineered to deliver exceptional shaping performance, efficiency, and long-term reliability in every application.

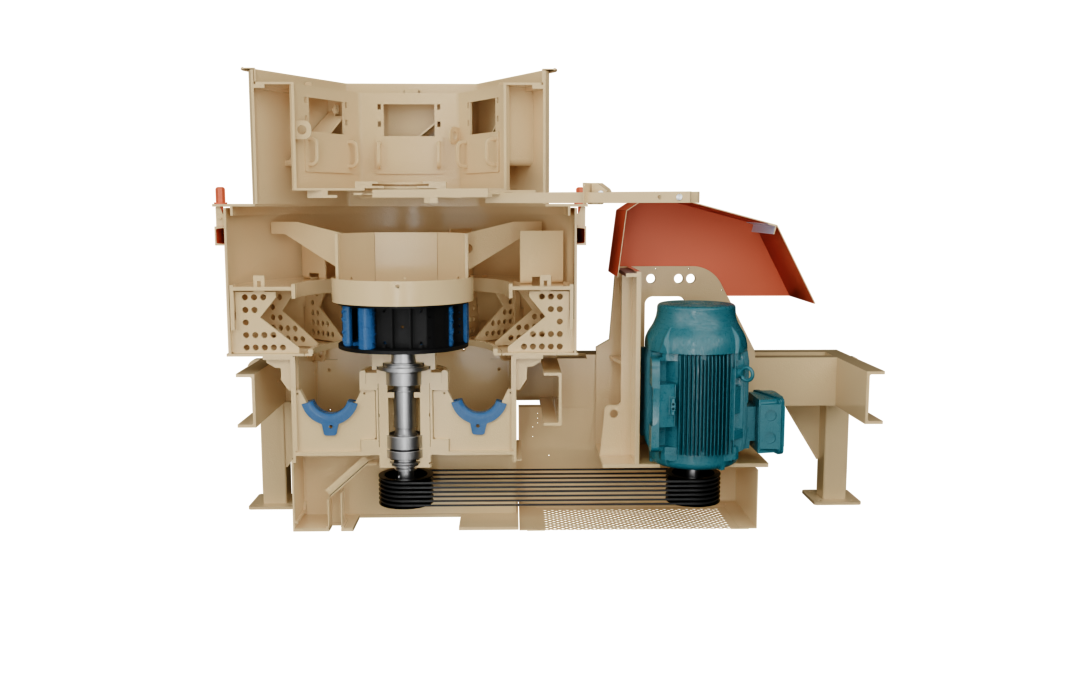

The rotor feed system distributes material evenly across the high-speed rotor, ensuring balanced impact energy and consistently shaped output.

Know moreDurable manganese wear liners maintain chamber geometry under high stress, ensuring consistent performance and fewer replacements.

Know moreCascade feed enables controlled material flow, reducing rotor load while improving energy efficiency, product shape, and component life.

Know moreThe central bearing cartridge provides robust support to the VSI rotor shaft, ensuring precise alignment, smooth rotation, and reliable performance under high-speed, heavy-duty crushing conditions.

Know moreDrive belts play a critical role in Vertical Shaft Impactor (VSI) crushers by transmitting power from the motor to the rotor with precision and reliability.

Know more

Heavy-duty housing withstands extreme impact and abrasive conditions, ensuring durability and extended machine life.

Precisely designed chamber geometry enhances particle-on-particle impact for superior shaping and higher reduction efficiency.

Balanced rotor ensures stable high-speed operation, delivering consistent output with reduced vibration and power loss.

Controlled material distribution reduces rotor load, improves throughput, and enhances energy efficiency.

Critical parts are manufactured from high-grade, wear-resistant materials to minimize downtime and maintenance costs.

Robust bearing support ensures smooth rotation under heavy loads, maintaining operational stability and reliability.

Smart access points simplify inspection and part replacement, reducing shutdown time and improving productivity.

Need more info? Please have a look at the tech specs of the watch. We’ve used latest machine & quality materials

| MODEL | MAX. POWER (KW) | ROTOR RPM | THROUGHPUT CAPACITY (TPH) | OUTPUT CAPACITY (TPH BELOW 5MM) | MAX FEED SIZE (MM) |

|---|---|---|---|---|---|

| MTV - 15 | 55 | 1300 - 1200 | 10 - 50 TPH | 5 - 25 | 40 |

| MTV - 16 | 75 - 100 | 1300 - 1200 | 50 - 120 TPH | 25 - 50 | 50 |

| MTV - 17 | 120 - 185 | 1300 - 1200 | 120 - 190 TPH | 50 - 70 | 50 |

| MTV - 18 | 185 - 250 | 1100 - 1800 | 190 - 250 TPH | 75 - 100 | 50 |

| MTV - 28 | 185x2 no | 1100 - 1800 | 250 - 445 TPH | 100 - 175 | 50 |

| MTV - 29 | 250x2 no | 1100 - 1800 | 445 - 600 TPH | 175 - 250 | 50 |

Got questions? We’ve got answers. If you have some other questions, feel free to send us an email to sales@mechtechengg.com

Mechtech VSI is suitable for crushing hard and abrasive materials such as granite, basalt, river gravel, and limestone, making it ideal for M-Sand and aggregate shaping applications.

The machine uses a particle-on-particle crushing principle with an optimized rotor and chamber design, producing high-quality, cubical aggregates with uniform gradation.

Yes. Features like the cascade feed system and balanced rotor design reduce power consumption while maintaining high throughput and crushing efficiency.

Mechtech VSI is designed with easy access points and wear-resistant components, allowing quick inspections, faster part replacement, and reduced downtime

Explore case studies from across industries where Mechtech screens have improved throughput, reliability, and plant efficiency under demanding conditions.