Dedicated Customer Teams & Agile Services

Our worldwide presence ensures the timeliness, cost efficiency compliance adherence required to ensure your production timelines are met.

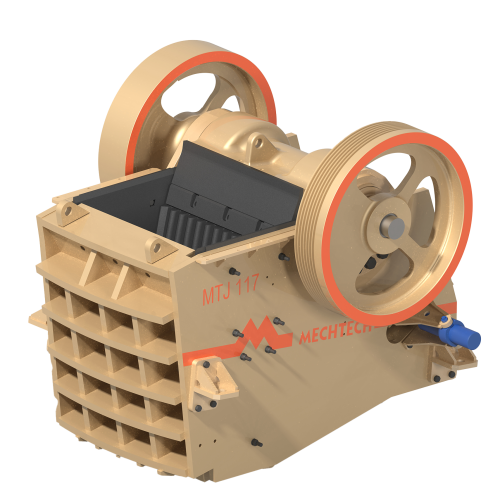

Overview

MechTech’s top-of-the-line MTJ-type jaw crushers are designed specifically for primary applications where resizing is the primary goal.

They allow the material to be handled within the confines of your crushing plant. The jaw crusher must have a good and homogeneous feed level to perform optimally.

Salient Features

HYDRAULIC JACKS

Hydraulic jacks help in the CSS range which has a significant effect on product gradation, capacity, and power draw.

LARGE FEED ACCEPTANCE CAPABILITIES

The large feed enables crush both tough feed materials like rocks in quarry fields and hard materiallumps in the mineral industry effectively and economically.

HEAVY-DUTY WELDED FRAME DESIGN

The plate takes heavy impacts from the material and protects the swing jaw, shaft, and bearing during crushing. It also helps to direct material into the crushing chamber.

HIGH CAPACITY WITH A HIGH REDUCTION RATIO:

The jaw crusher's bulk density, crushability, and size distribution result in a high capacity and reduction ratio

OPTIMIZED NIP ANGLES

Jaw crushers have nip angles between 16–23°.A good nip angle means a high throughput capacity of the crusher.

| Jaw Crusher | Average Capacity in Tons/Hr, with Jaw Setting(Closed Setting) | HP | RPM | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Inches | 1" | 1 1/2" | 2" | 2 1/2" | 3" | 3 1/2" | 4" | 5" | 6" | 7" | 8" | |||

| MM | 25 | 38 | 50 | 63 | 75 | 90 | 100 | 125 | 150 | 175 | 200 | |||

| 24" X 12" | 610 X 305 | 28" | 33" | 43" | 48" | 55" | 62" | - | - | - | - | - | 50 | 60 | 24" X 15" | 610 X 381 | - | 40 | 45 | 53 | 60 | 70 | - | - | - | - | - | 50 | 280 |

| 30" X 15" | 762" X 381" | - | - | 50 | 63 | 70 | 80 | 88 | - | - | - | - | 50 | 280 |

| 30" X 20" | 762" X 508" | - | - | - | 68 | 72 | 80 | 98 | - | - | - | - | 60 | 280 |

| 36" X 24" | 914" X 610" | - | - | - | - | - | 80 | 90 | 125 | 140 | 175 | 200 | 100 | 280 |

| 36" X 28" | 914" X 711" | - | - | - | - | - | 115 | 140 | 165 | 190 | 215 | 240 | 100 | 280 |

| 42" X 32" | 1067" X 813" | - | - | - | - | - | 125 | 150 | 175 | 200 | 250 | 275 | 125 | 280 |

| 44" X 32" | 1118" X 813" | - | - | - | - | - | - | 165 | 190 | 230 | 280 | 330 | 150 | 280 |

| 42" X 36" | 1067" X 914" | - | - | - | - | - | - | 175 | 200 | 250 | 300 | 350 | 150 | 280 |

| 44" X 36" | 118" X 914" | - | - | - | - | - | - | 200 | 225 | 275 | 330 | 375 | 200 | 280 |

FAQ

Yes, we offer installation and maintenance services to ensure that our equipment operates at peak performance throughout its lifespan.

Yes, we offer customized solutions to meet the specific needs of our customers. Our team works closely with customers to understand their unique requirements and develop tailored solutions.

Yes, we offer training for equipment operators to ensure that they are properly trained on the use and maintenance of our equipment.

Our crushing equipment is manufactured in our state-of-the-art facility, located in Vadodara, Gujarat. We use the latest technology and equipment to ensure the highest level of quality and precision.