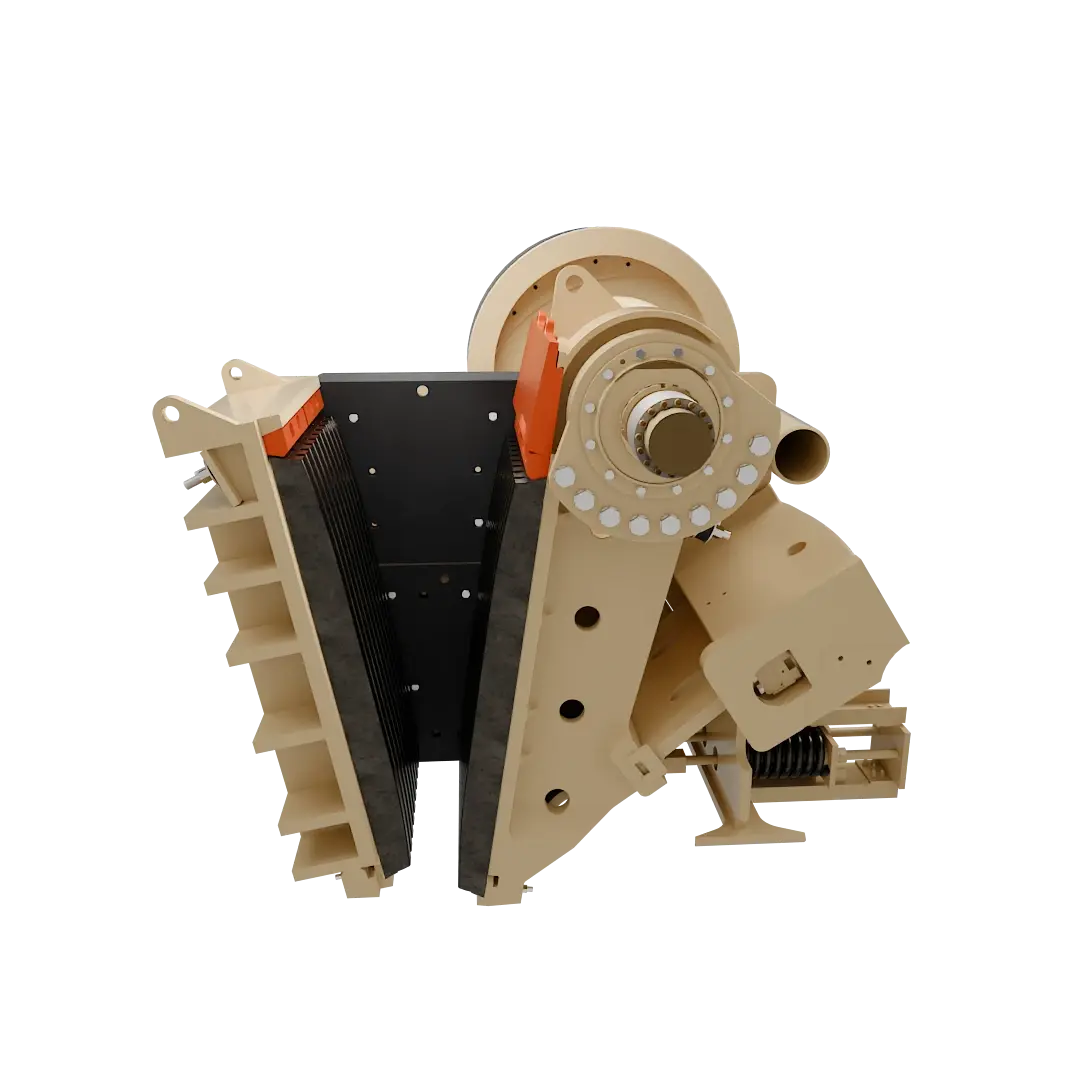

Engineered to Endure. Crafted to Perform.

From massive boulders to controlled output, the Mechtech Jaw Crusher is designed for continuous crushing excellence. Its durable construction, optimized chamber, and dependable motion combine strength with operational intelligence.

Play