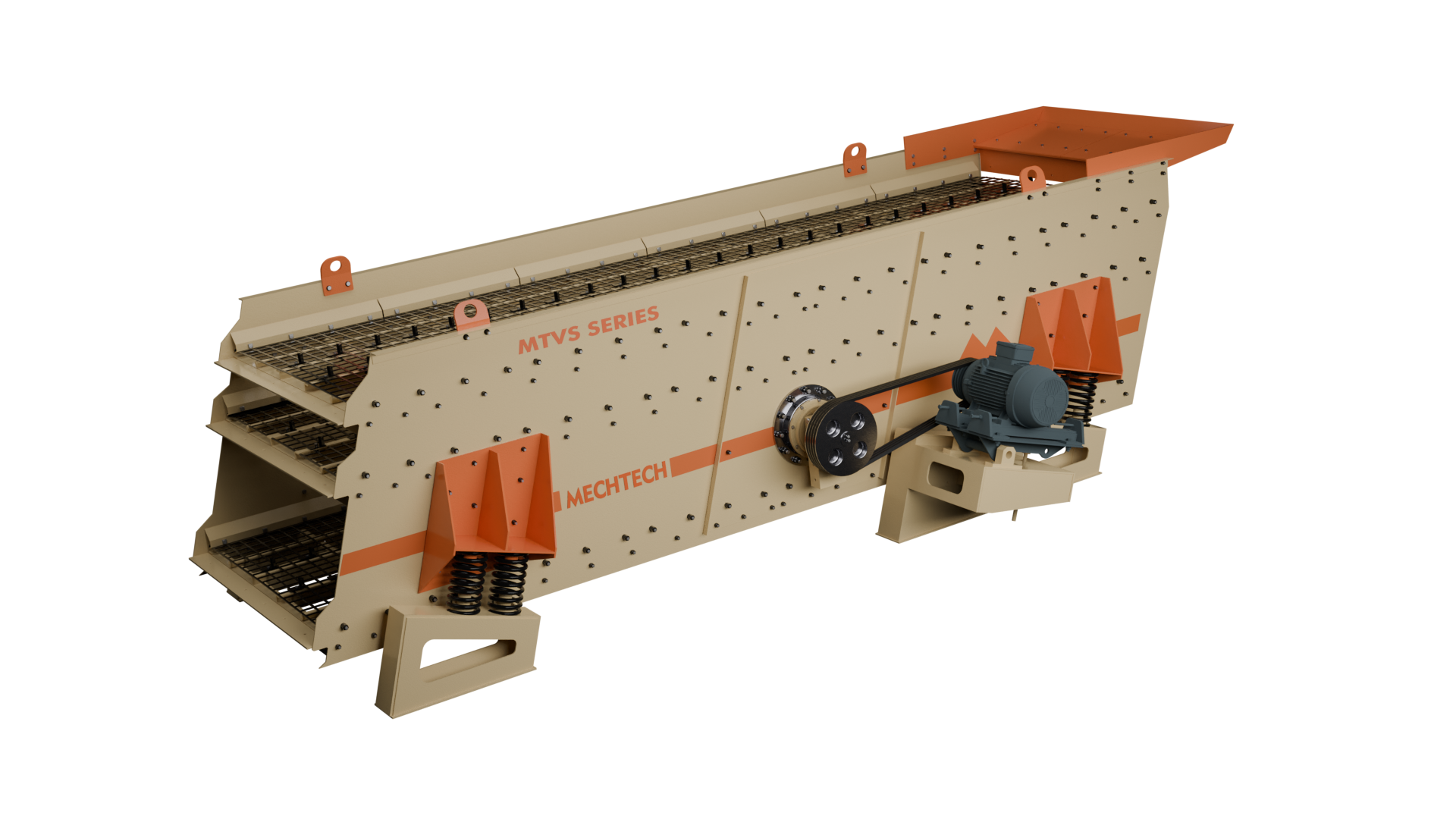

Built to screen. Made to last.

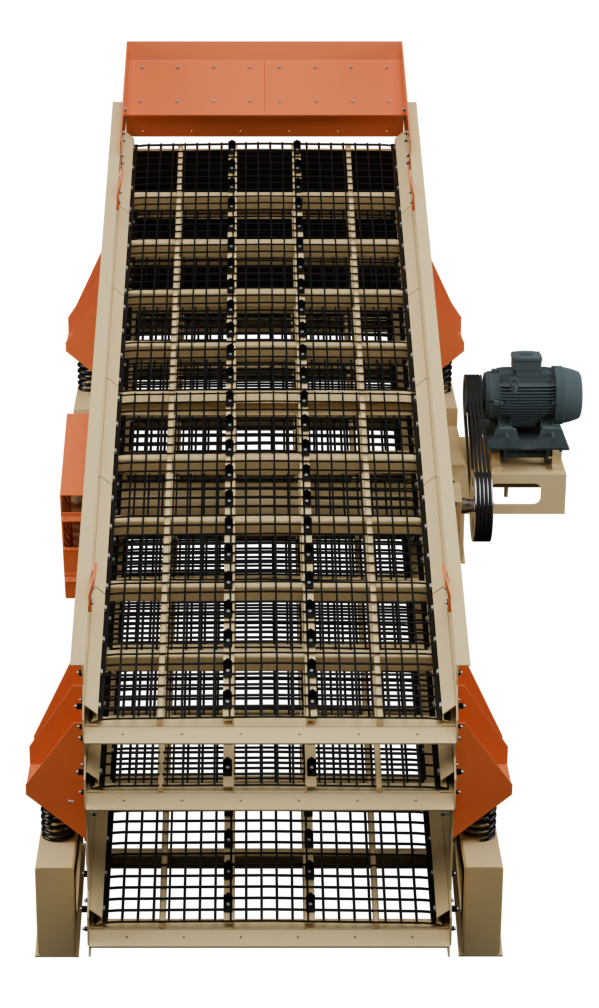

Meet the MTVS Series. A high-efficiency vibrating screen built for fine-tuned separation and precise material flow.

Reliable in tough conditions. Compact in design.

Optimized for better results.